Your partner in coil fed laser solutions

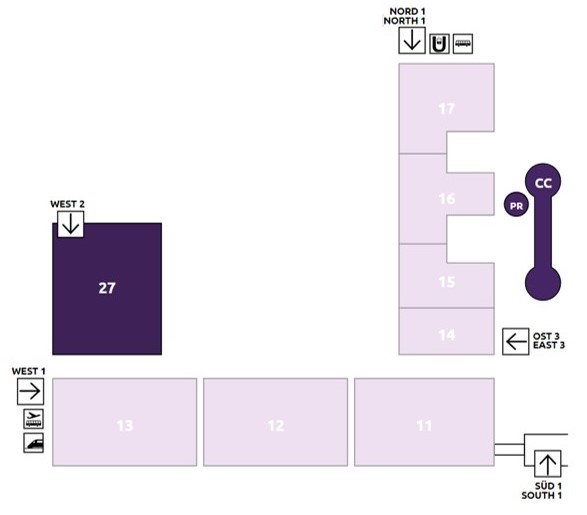

Visit us at Euroblech 2018!

As the leading coil fed laser solutions specialist, this year we will be located in a new Hall:

Hall 27, Stand H132

DANOBAT LB coil fed laser machine will be exhibited with the latest updates. Come and see how flexible your production process can get. We will show you the production of our latest applications: cookware, HVAC, automotive industry, roofing industry, silos and tanks, among others.

ADVANTAGES OF COIL FED LASER TECHNOLOGY

Greater flexibility

You can achieve a more flexible manufacturing process and better results in the production of different part types.

Optimal system for small batches

The optimal manufacturing system for small and medium batches: it allows greater savings in time and a better adaptability to customer needs.

Energy saving

DANOBAT LB is more efficient and consumes less energy than conventional manufacturing methods.

Savings in maintenance

DANOBAT LB adapts to each part type, thus allowing you to avoid big maintenance tool maintenance and purchase expenses.

Eliminate down time

DANOBAT flexible coil fed solution allows the possibility of manufacturing different types of parts at the same time, consequently reducing production downtime dramatically.

Space optimization

Coil fed laser solutions take up much less space than other conventional manufacturing technologies and also require more simple installation conditions.

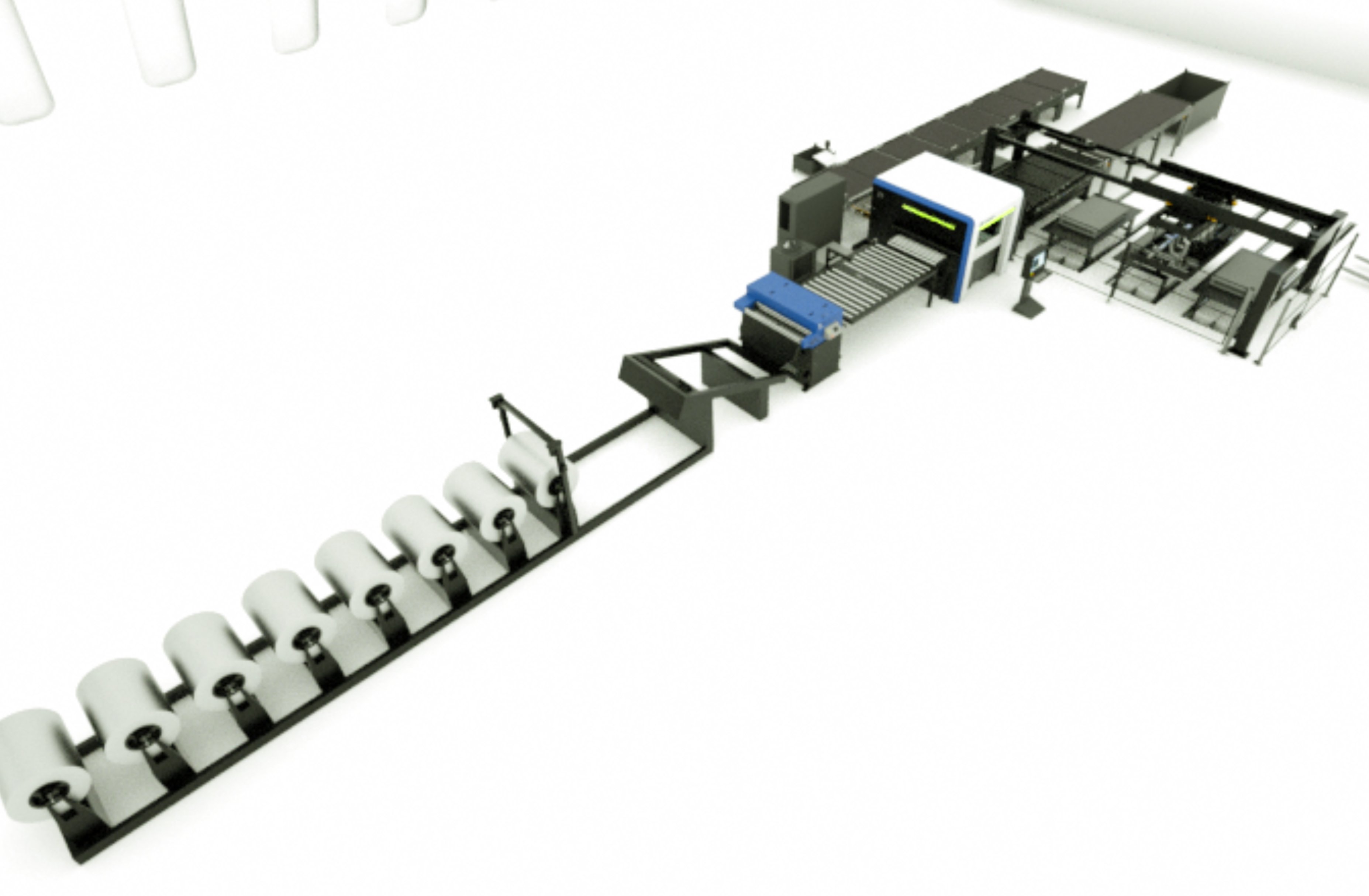

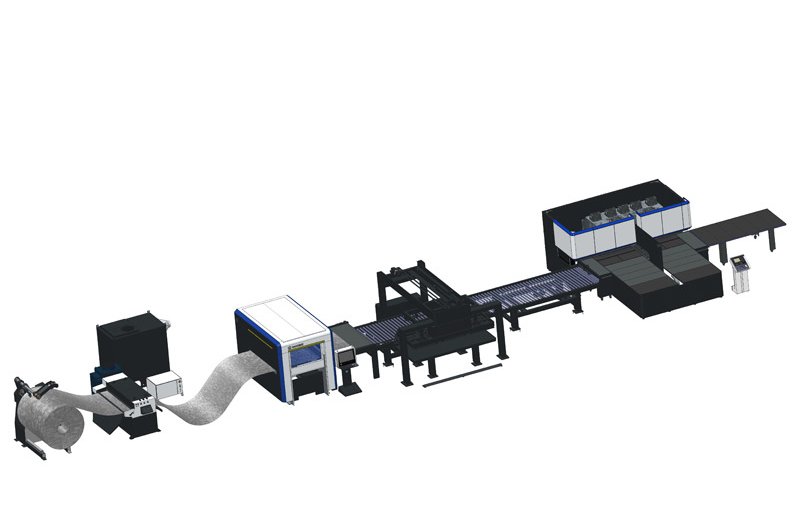

OUR COIL FED LASER BLANKING REVOLUTIONIZES THE PRESS LINE INDUSTRY

DANOBAT LB coil fed laser leaves conventional press blanking behind: it combines the advantages of both laser cutting technology and the use of coil as the feeding material. Reduce your cost per piece and achieve greater flexibility in your production.

NEW APPLICATIONS COMING UP AT EUROBLECH

Discs

Knives

Tanks

Silos

Kegs

AUTOMOTIVE INDUSTRY

HVAC

Facades

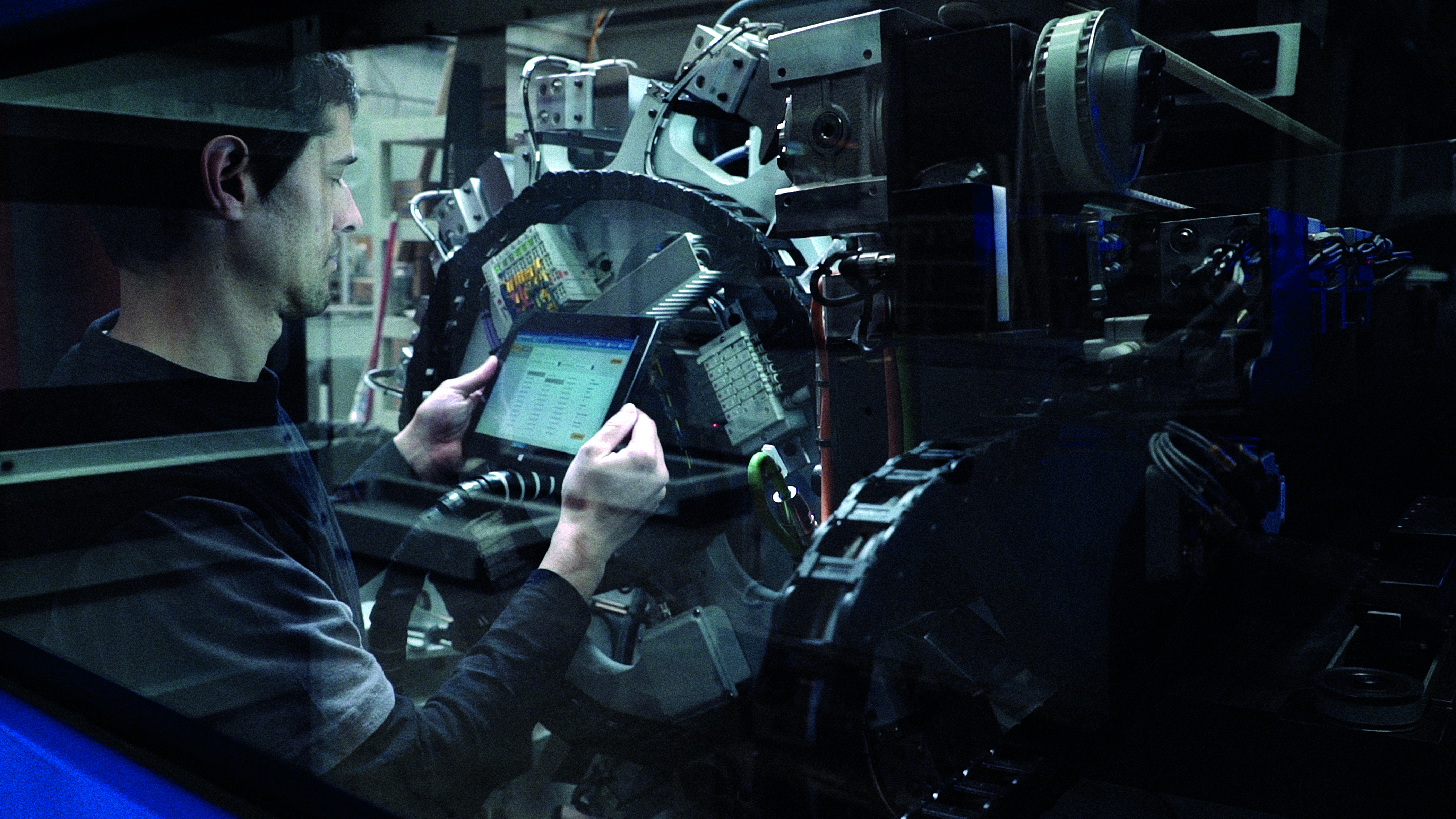

DANOBAT DIGITAL

Experience digitalization wherever you are

As a leader in technological innovation, DANOBAT has now developed an exclusive HMI System and Data System for you to monitor your machines and optimize your production processes remotely through your PC, tablet or phone in real time, wherever you are.

Among the digital services that the DANOBAT Sheet Metal Division will present at EUROBLECH, the integrated HMI System stands out as it offers innovative features for a better management of DANOBAT Coil-fed Laser: it allows the user to access and manage information about the production status in real time.

Increased machine accessibility, control management, programming assistance and visualisation of special machining cycles are among the main advantages of this cutting-edge feature. Furthermore, it also includes an interactive maintenance module that notifies the user when preventive maintenance measures need to be taken.

Other features also offer assistance to fault location and recommended recovery plans, a Computerized Maintenance Management System and energy consumption charts.

DANOBAT Data System is the other key digital solution that our coil fed laser will present at EUROBLECH. This powerful analytical tool collects machine generated data to achieve an optimal performance. This feature allows live process monitoring, alarm and energy consumption management and besides, it generates productivity reports.

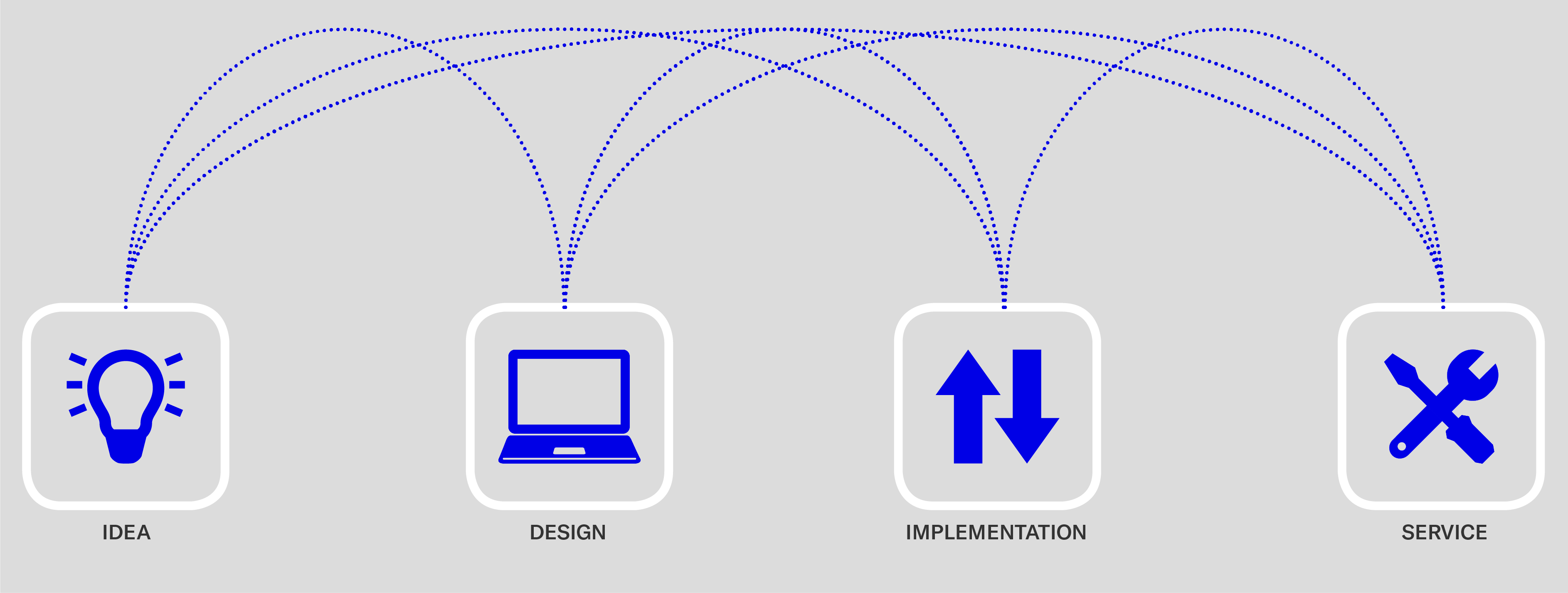

TAILOR MADE CUSTOMIZATION FOR YOUR LB

From the idea to the service

Share your needs with us and we will come up with a customized project, from the idea to the service.

We customize your laser blanking machine in order to get the best solution for you